Welded Wire Reinforcement

Welded Wire Reinforcement

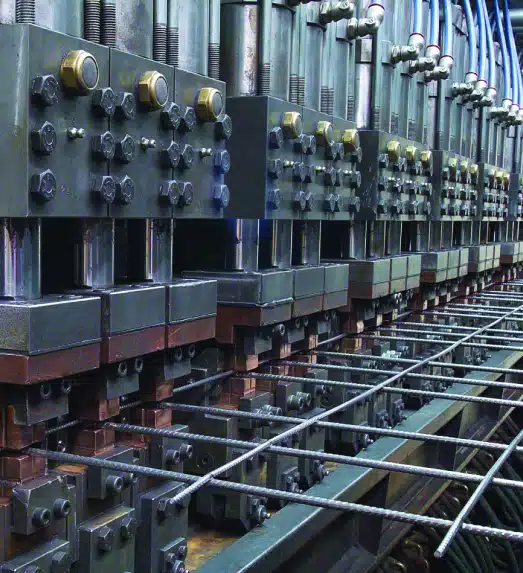

DWR® Welded Wire Reinforcement Mesh is a welded steel wire reinforcement mat designed for reinforcing concrete. Also known as Wire Mesh, it can be produced with W-Smooth/Plain wire or D-Deformed wire.

Our WWR can be made with wire ranging in size from D/W 1.28 to D/W 31 and can be used in many cases in conjunction with or as a substitute to rebar, which mostly requires manual placement.

APPLICATIONS

+Our welded wire mesh delivers proven performance across numerous construction applications such as:

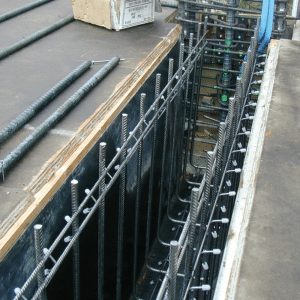

- Pre-cast structures

- Slab on grade

- Structural Slabs

- Tilt-up construction

- Barrier walls

- High rise towers

- Stirrup tie cages.

ADVANTAGES

+The main advantages of using our welded wire reinforcement include:

- High strength steel and standards

- Easy and fast to install.

- Short delivery lead times.

- Offers savings in labor cost up to 75%

STANDARDS & CODES

+Our products fully comply with the following construction standards, codes, and specifications:

- ASTM A1064

- IBC/ACI

- AASHTO

Benefits

HIGH STRENGTH STEEL

Welded intersections minimize random cracks and effectively control separation.

EASY AND FAST TO INSTALL

Can be installed as much as 10 time faster, promoting accelerated project completions and significantly reduced labor cost.

SUSTAINABLE STEEL

Due to the EAF technology and our energy efficiency investments, our process is one of the lowest CO2/product rates in North America.

Specifications

FEATURES

STRUCTURAL QUALITY

- Cold rolled wires, positively deformed and pre-straightened.

- Prior to fusion welding, individual wires are sheared to

required strength. - Precise and permanent spacing.

- Resists curling due to fusion welded intersections

OPTIMAL CRACK CONTROL

- Welded intersections minimize random cracks and effectively control separation.

- Positive (raised) deformation, assures superior concrete bond strength.

- Total square footage of material acts as an integrated unit.

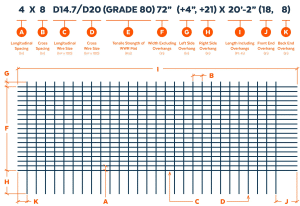

NOMENCLATURE

NOMENCLATURE

STANDARD BUILDING WELDED WWR MESH ROLLS

| ITEM CODE | DESCRIPTION | UNITS T/L |

| 19224 | 6″X6″ 10/10 (D1 .4) 5’X150′ (9/BUNDLE) | 306 |

| 83557 | 6″X6″ 10/10 (D1 .4) 5’X150′ (18/BUNDLE) | 324 |

| 9480 | 6″X6″ 10.5/ 10.5 (W1 .28) 5’X150′ (18/BUNDLE) | 324 |

| 84977 | 6″X6″ 6/6 (D2.9) 5’X150′ (9/BUNDLE) | 162 |

| 9479 | 6″X6″ 10/10 (W1 .4) 5’X50′ (17/BUNDLE) | 476 |

| 84271 | 6″X6″ 10/10 (W1 .4) 5’X150′ (9/BUNDLE) | 324 |

| 84063 | 6″X6″ 10/10 (W1 .4) 7’X 200′ (9/BUNDLE) | 126 |

| 85223 | 6″X6″ 10/10 (W1 .4) 6’X150′ (9/BUNDLE) | 272 |

| 85219 | 6″X6″ 10/10 (W1 .4) 5’X 200′ (14/BUNDLE) | 238 |

Applications

Discover the Latest Trends and Expertise in Construction with Our Blog

Navigating Steel Rebar Prices: Trends, Impacts, and Solutions

The world of steel rebar prices is extremely dynamic. It is a world where the ebb and flow of costs ...

READ MORE ➔Elevating Structures with Innovative Steel Beam Solutions

Steel beams, with their ingenious design and structural strength, play a transformative role in cont...

READ MORE ➔The integral role of steel rebar in modern construction

The essence of steel rebar lies in its ability to provide tensile strength to concrete, creating a c...

READ MORE ➔Request a Quote

Our team of technical experts can review your project details and provide advice on the best fabricated rebar, bars, beams, wire mesh, and other products to suit your project needs. Contact us today.