As we know, wire mesh is an essential component in many construction projects, and selecting the right type can make a significant difference in the outcome. With so many options available, it can be challenging to determine which one is best suited for your needs.

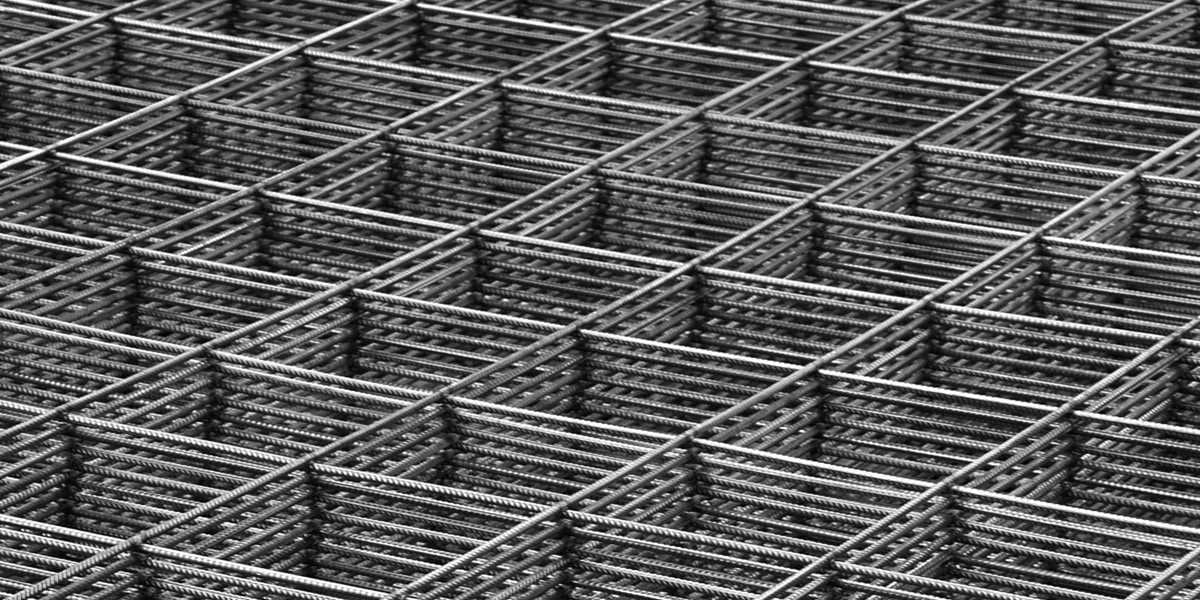

Wire mesh is a highly versatile material used for reinforcing concrete in all types of construction projects, since it is one of the most adaptable materials in the market. It is also known as Welded Wire Reinforcement (WWR), this welded steel structure is produced from plain or deformed wire, and offers excellent durability and strength.

In addition to its well-known strength standards, welded wire reinforcing mesh offers several advantages like significant cost reduction, ease and speed of installation, as well as, qualities that shorten the time to conclude a construction job.

In this article, we will delve into the properties and characteristics of WWR, and explore its wide range of applications in the construction industry.

Which steel reinforcement products to choose?

- Material. Wire Reinforcement Mesh can be made of Smooth/Plain steel wire, deformed steel wire, Stainless steel wire, and Galvanized steel wire. The last two standing out for their high corrosion resistance and tensile strength of 367741 N/in².

- Shape and size. Commonly, the mesh is found in square and rectangular shapes where the common openings are 4 by 6 inches and 6 by 6 inches and the mesh can be produced in lengths and the mesh can be produced up to 118 inches in width. When this material is delivered in the form of a flat sheet, ready for laying, the usual length is from 10 to 20 feet. If delivered in rolls, the most common lengths are 50, 100, 150, and 200 feet.

- Cutting. Cutting the mesh simplifies its use and reduces work time on site.

- Vibration. It is best to use welded mesh to ensure that the concrete mix is properly distributed and that the mesh is implanted, avoiding vibration cracking.

Presentations and uses

As we said above, welded wire mesh is a product made up of a series of wires that are threaded and secured by electric welding. Its openings may vary depending on the type of wire and the purpose the product will serve.

To get the perfect fit, this material is available in rolls or sheets. Regardless of the presentation you choose, you should know that steel mesh is impossible to disassemble without the use of external force.

In the manufacture of welded mesh, the wires are threaded with the objective of uniformly welding the intersections simultaneously, quickly and efficiently, eliminating traditional ties.

On the other hand, rolls or sheets can be manufactured from thinner wires when a mesh with larger openings are required without the material losing strength or becoming unstable. Smooth/Plain steel wire or Deformed steel wire are used for this purpose

Some applications of a wire reinforcing mesh are Precast Structures, Slab on Grade, Tilt-up construction, Tunnels, High-Rise Towers, and Foundations.

Despite the advantages welded wire reinforcement mesh offers, it is advisable to keep in mind that its material properties and the right choice of product alone do not guarantee optimal performance on the construction site. It is also essential to consider quality as a key factor when choosing a construction material supplier.

Aware of our role in the industry, at DWR Reinforcing and Steel solutions we have state-of-the-art technology that allows us to manufacture high quality structural products.

Before going to market, our products undergo a laboratory and an on-site testing by experienced quality control teams and are backed by certifications.

This is why we can provide a wide range of diameters and dimensions of steel reinforcement products, which are available in rolls and sheets to meet and optimize the design requirements your projects demand.