With the average height of wind turbines being 280 feet, and the very tallest being over 850 feet, their foundations must be rock-solid. There are several types of turbine foundations, such as monopile or jacket foundations, but many rely on massive concrete bases to keep the turbines stable.

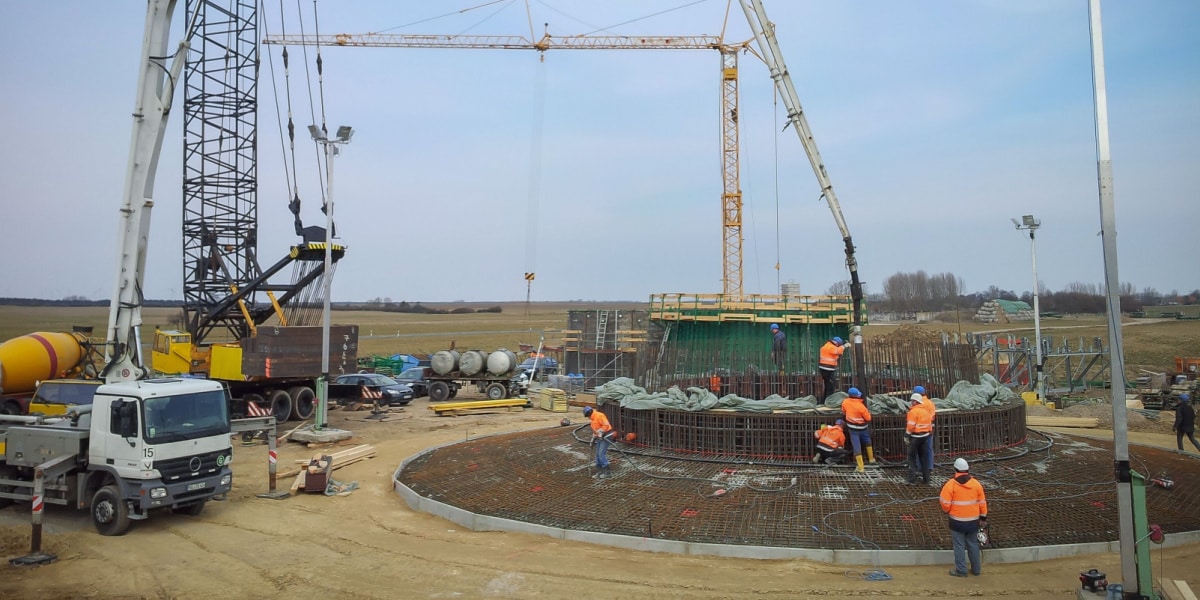

However, the wind forces these turbines experience mean that concrete alone is insufficient for long-term support. In most modern designs, a cage of rebar is set into the excavated foundation area first, and concrete is poured over the top.

Rebar in Wind Turbine Construction

Fabricated rebar is a material commonly used to add strength to building structures and foundations, so it’s no surprise that wind turbines also rely on it. Let’s examine the properties that make rebar useful for strong turbine foundations.

What Role Does Concrete Reinforcement Play in Wind Turbine Construction?

While it’s fair to say that adding rebar to concrete dramatically increases structural strength, it’s not the whole story. Concrete on its own is strong and durable, but not nearly so much as steel.

The rebar provides a “skeleton” that sits inside the concrete, but it’s also not fair to give the impression that the rebar is doing the actual work of supporting the structure. Instead, rebar and concrete work synergistically and are both necessary to the finished foundation.

The way rebar is formed gives it a surface that bonds particularly well to concrete and allows the two materials to share loads. In addition, rebar is far more elastic than concrete, which means that cracking concrete can show that a structure is experiencing too much weight without becoming dangerously unstable.

Thanks to much testing, the strength and fatigue properties of reinforced concrete are well documented. Given the characteristics of these materials, when paired, they make for an ideal foundation for wind turbines.

What Characteristics Make Rebar Ideal for Turbine Foundations?

One of the most critical features of rebar regarding its use in wind turbines is its yield. Below steel’s yield, the surrounding concrete may crack, but the rebar will rebound.

Wind turbines will experience wind forces that may subtly twist and push the entire tower in ways that may be invisible to the naked eye. Still, those forces are there, and they can cause weaker materials to fail catastrophically.

Another benefit of rebar for turbines is that its shear strength is nearly the same as its longitudinal yield strength. This is because many materials exhibit immense rigidity when force is applied in one direction, only to become weak when force is applied in a different direction.

Rebar exhibits uniform properties in all directions, whether stretched, compressed, twisted, or struck.

The Future of Steel Reinforcement in the Renewable Energy Industry

To develop safer and stronger foundations, one advancement in construction may involve changing to stronger types of rebar. Rebar strength is not dependent on its thickness — 70 KSI rebar will fit in the same space as 60 KSI rebar.

In fact, higher strength rebar allows for the use of less rebar, allowing poured concrete to flow through the rebar skeleton far easier. This setup avoids air gaps that can weaken the entire structure.

Because stronger rebar isn’t thicker or heavier than weaker rebar, it also takes less energy to transport to a job site. The finished rebar skeleton can then be moved into place with a smaller, less powerful crane.

And if the bars are threaded, they can be joined with junctions instead of welded, reducing the labor and material required to make the structure. All these advancements combine to make the wind turbine less wasteful and reduce its carbon footprint.

Learn more about how steel is used in the renewable energy industry.

DWR Offers Concrete Reinforcement for Wind Farms

Since wind power aims to create renewable, clean energy, the materials that go into making wind turbine foundations should be as ecologically friendly as possible. It only makes sense to source wind farm construction materials from the recycled waste stream.

DWR specializes in superior quality steel reinforcing bar that is also sustainable. With 21 steel recycling centers, DWR reduces waste by ensuring that materials that can be used will be used. Choose our sustainable steel solutions for solid and long-lasting foundations that need a sizable physical footprint and a small carbon footprint.